Table of Contents

In today’s fast-evolving construction industry, precision and efficiency are critical. Traditional manual surveys are giving way to advanced digital methods like Scan to BIM, which combines the power of 3D laser scanning with Building Information Modeling (BIM). But how exactly does Scan to BIM work, and why is it becoming an essential tool for architects, engineers, and facility managers?

This blog breaks down the process, explains its growing importance, and highlights how it can reshape your project outcomes.

What is Scan to BIM?

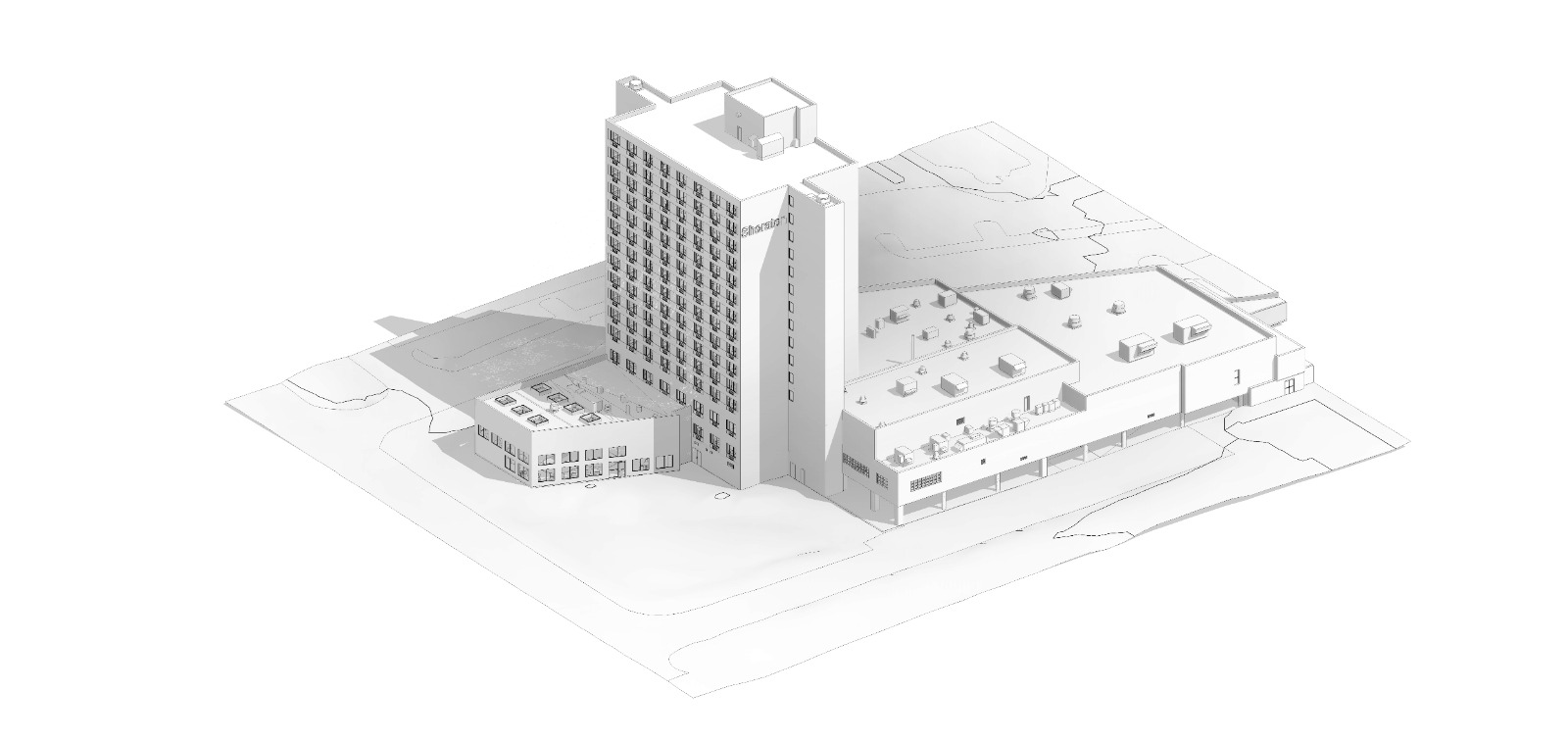

Scan to BIM is a technology-driven process that involves capturing a physical space or structure using 3D laser scanners and converting that data into a digital BIM model.

Scan to BIM is the process of using 3D laser scanning to capture an existing building or site and convert that data into a digital Building Information Model (BIM). This ensures accurate as-built documentation for design, construction, and facility management

The process typically produces a point cloud, a collection of millions of data points that represent the shape and size of the structure. This data is then imported into BIM software like Autodesk Revit, where it is modeled to reflect real-world dimensions and conditions.

How Does the Scan to BIM Method Work?

The Scan to BIM method is a multi-step workflow that blends field data capture with digital modeling:

Step 1: 3D Laser Scanning

High-resolution laser scanners scan the building or structure to capture every surface detail.

Step 2: Generating the Point Cloud

The scanner creates a dense set of spatial data (point cloud), representing the scanned object’s geometry.

Step 3: Data Import into BIM Software

Point cloud files are imported into BIM platforms like Revit to begin the modeling process.

Step 4: BIM Model Creation

Using the point cloud as a reference, architects and engineers generate a precise 3D model, including architectural, structural, and MEP elements.

Step 5: Validation and Use

The BIM model is validated for accuracy and then used across the project lifecycle—from planning and construction to facility management.

Understanding LOD in Scan to BIM

BIM models from scanning can be developed at different Levels of Development (LOD):

- LOD 200: Basic geometry for early design.

- LOD 300: Accurate layouts for coordination.

- LOD 400: Fabrication-level details.

- LOD 500: As-built conditions for facility management.

This flexibility allows teams to generate the right level of detail depending on the project phase.

What Are the Benefits of Scan to BIM?

Scan to BIM offers a wide range of benefits that go beyond traditional surveying:

- Improved Accuracy: Laser scanning minimizes human error and captures exact as-built conditions.

- Faster Renovation & Retrofit Planning: Perfect for old structures or undocumented buildings.

- Reduced Site Rework: With accurate models, clashes and design flaws can be identified early.

- Enhanced Collaboration: A single BIM model can be shared across disciplines.

- Supports Digital Twins: Lays the foundation for smart building systems and lifecycle management.

- Time & Cost Savings: Efficient scanning and modeling reduce turnaround times and project costs.

What Are the Benefits of 3D Scanning in Construction?

3D scanning plays a vital role in the success of Scan to BIM workflows:

- Detailed & Comprehensive Capture: Every corner and element is scanned with millimeter precision.

- Quick Onsite Data Collection: Large buildings can be scanned in hours, not days.

- Repeatable & Reliable: Data can be revisited anytime during design or execution.

- Ideal for Complex Structures: Works well even in geometrically irregular or cluttered environments.

Scan to BIM vs. Traditional Surveying

Here’s a quick comparison that highlights the difference:

Feature | Traditional Surveying | Scan to BIM |

Accuracy | Moderate | High (mm precision) |

Speed | Days to weeks | Hours to days |

Data Format | 2D drawings | 3D intelligent model |

Collaboration | Limited | Multi-discipline ready |

Cost Efficiency | Higher rework risk | Lower lifecycle costs |

Applications of Scan to BIM in Real-World Projects

Scan to BIM is widely used in:

- Historical Building Renovation – Preserving architectural details during restoration.

- Construction Project Validation – Ensuring the site matches design intent.

- Facility Management – Maintaining and managing buildings post-construction.

- Infrastructure Projects – Highways, tunnels, and bridges modeled for upgrades.

- Real Estate Development – Accurate models improve space planning and visualization.

- Healthcare Projects – Retrofit hospitals with minimal operational disruption.

- Industrial Plants & Oil & Gas – Capture complex piping and MEP systems.

- Airports & Transit Hubs – Improve planning in high-traffic environments.

Future Trends in Scan to BIM

The future of Scan to BIM is closely linked with emerging technologies:

- AI & Automation: Faster point cloud-to-model conversion.

- AR/VR Integration: Virtual walkthroughs of scanned sites.

- Digital Twins: Real-time operational data layered over BIM.

- Cloud Collaboration: Multi-team access to large point clouds.

Challenges and Considerations

While highly effective, Scan to BIM implementation comes with certain challenges:

- High Initial Investment – Scanners and software can be expensive.

- Skilled Expertise Needed – Requires trained professionals for scanning and modeling.

- Large Data Handling – Point cloud files are data-heavy and need high-performance systems.

- Accuracy Depends on Scan Quality – Poor scans lead to faulty models.

Conclusion

Scan to BIM is no longer a futuristic concept—it’s a practical solution being adopted by smart construction firms and facility managers today. By combining real-world data with digital modeling, it enables more informed decisions, fewer errors, and greater efficiency throughout a building’s lifecycle.

Whether you’re planning a renovation, managing an asset, or designing new infrastructure, Scan to BIM is a smart investment in precision and performance.